Overview

The bad cvt stepper motor symptoms indicate the possibility of harm to your engine and the vehicle. They could affect your vehicle’s performance if you you they are repaired properly.

These are typical symptoms that are easy to identify, like sluggish acceleration, jittery sounds, etc.

In certain situations, the defective motor may stop working entirely and hinder your car from working.

Therefore, fixing a damaged stepper motor is crucial for maintaining the performance of your car.

We’ll discuss the signs of a defective CVT stepper motor, which requires an upgrade or repair to allow your Nissan to function at its best.

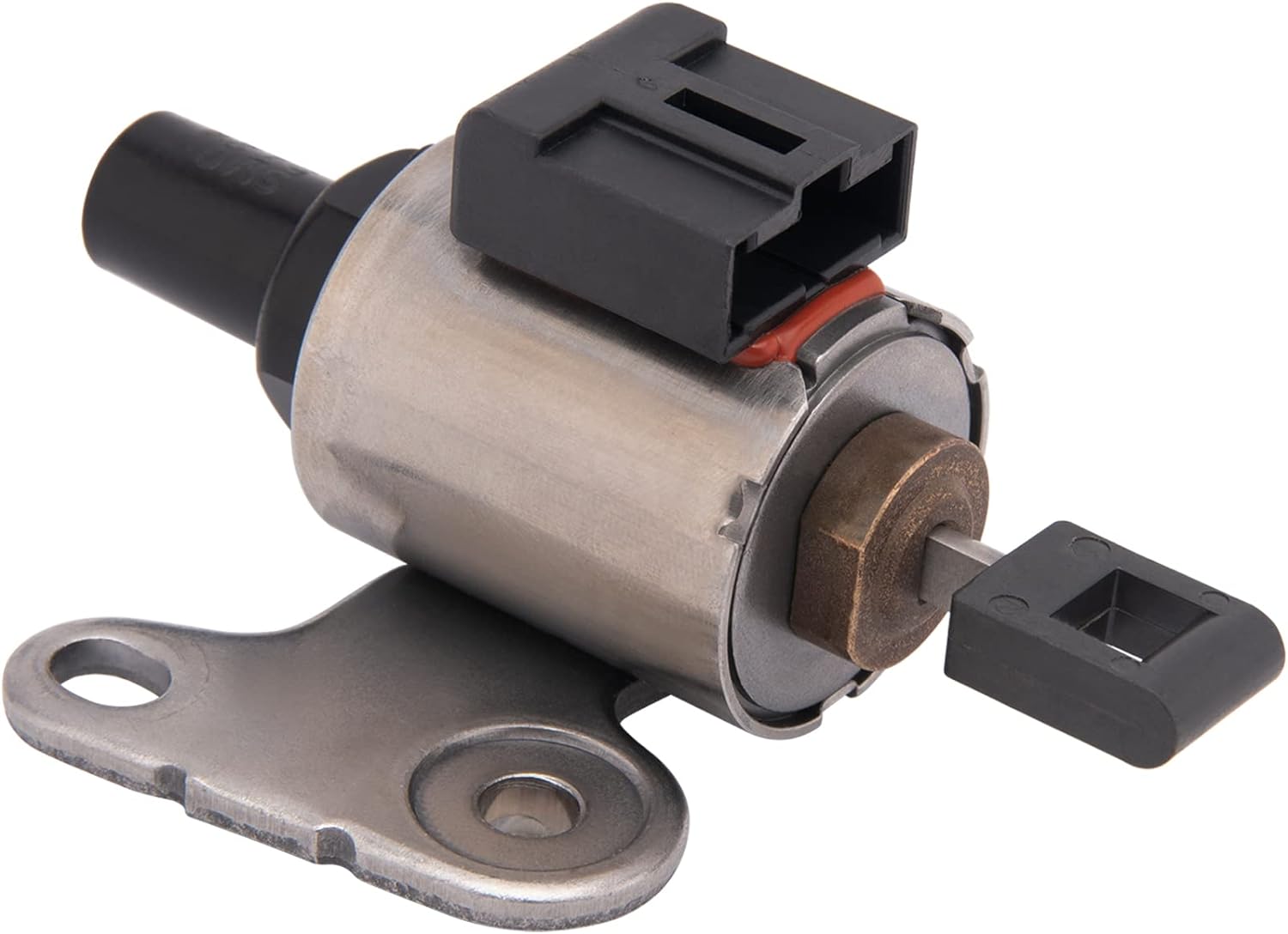

What is a CVT Stepper Motor?

Stepper motors are an element of many Nissan models equipped with CVT transmission.

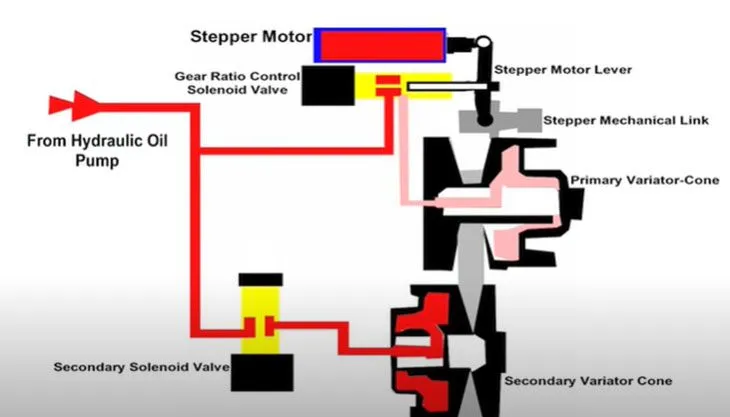

The transmission is equipped with fewer moving parts than the standard automatic one, which includes two pulleys fitted with chains that are high-strength or belts.

A stepper motor in the form of a CVT (Continuously Variable Transmission) is in sync with the ratio control valve as well as the arm.

The control module for transmission allows the motor stepper to contract or expand to change the valve’s location, controlling the ratio by transmitting messages to the.

The transmission sends an error code P1777 or P1778error error code back to the computer in the vehicle if it finds a problem with the transmission ratio.

This will activate this Check Engine Lamp to alert you of the possibility of a problem with your vehicle’s transmission.

What are bad cvt stepper motor symptoms?

If your car slows down or ceases to function, The main cause is a motor not working correctly.

Additionally, you can look for common signs, for example, slow acceleration, unusual noises, winding damage, incorrect driver, or short circuit malfunction.

If your motor needs to be fixed, pay attention to the mentioned Nissan poor stepper motor warning signs.

The sections below describe each. Let’s take a review of each symptom in greater detail!

Hesitant Cars

The car might stall due to a defective stepper motor. This is among the unpleasant CVT stepper motor warning signs if you’re trying to shift to different roads.

Additionally, this issue is hazardous and a nuisance while driving, particularly in busy and fast rush hour.

Abnormal Operation If Car is Moving

If the motor is running but can’t obey pulse commands or if there is an unusual noise or vibration, This could result from a defective stepper motor.

So, you need to provide your engine with another inspection and repair.

Slow Acceleration

If your car’s acceleration is slower than usual, the defective motor in your stepper is to be blamed. In the long run, this can be unsatisfying (or even hazardous) for you.

Therefore, pay attention to it when your vehicle speeds up slowly.

Position Error When Car Moves

Each step that the stepper motor of your Nissan makes is a mistake. But, they’re not continuous and always fall lower than the +/-0.05deg specifications.

Being aware of when errors happen, and the exact number number of errors that occur is essential to ensure you can troubleshoot the issue.

Therefore, you must identify the patterns and precisely calculate the error in position using the actual position and the position you want to be in.

Additionally, the linear error has to be transformed from inches or millimeters to pulses, degrees, or steps. The Nissan stepper motor is connected to the ball screw.

Drag or Reverse

A damaged stepper motor could cause your car to slide around while changing gears. This is also an obvious sign that indicates an opportunity for the driver.

Strange Noise

A squeaky sound beneath the hood could be a regular and severe sign of a failed stepper motor.

If you press the accelerator, your stepper motor could be damaged if you hear whining, grinding, or any other strange sound.

Taking your car to a repair shop to see an expert mechanic who can diagnose and repair the issue when you notice these symptoms is essential.

Inoperative Stepper Motor

The stepper motor usually fails when the engine is running. However, your vehicle is still stationary. This warning signal alerts you to the problem with stepper motors with its revs, but the engine doesn’t run.

Owners of CVTs may experience premature failures in certain situations. Nissan has solved this issue by launching a range of hardware modifications in the 2013 model year.

High-pitched Squeal Audio Noise

The noise from the engine produces a loud noise that squeals.

Noise could impact the control of chopping by the Nissan stepper motor. In most cases, audio noise affects only the control circuit because of problems with stability within the circuit.

The frequency of the efficient chop varies between the desired frequency and the subharmonic frequency. The frequency of voltage spikes and the amount of electrical sound can also shift the motor control frequency.

If that frequency changes as soon as that frequency changes, it is then that the Nissan stepper motor ceases rotating or reduces speed.

A Faulty Driver

A driver that is not working correctly could be one cause of Nissan stepper motor problems. This happens because the power supply cannot regulate the voltage at peak.

It is essential to select the suitable clamp diode for the task. Also, it is crucial to select the diode that will match the speed switch of the stepper motor.

This can reduce the voltage at which the power source to the motor.

The stepper motor’s clamp diodes should be similar to the output transistors’ switch time.

Motor Failed To Turn

A stepper motor will only rotate once it gets enough electricity from the power supply. Additionally, the motor could not turn if the current isn’t strong enough to move the stepper motor shaft.

Setting the desired rate needs constant torque.

If the speed setting is higher than the needed torque, the motor of the stepper will not rotate, no matter how much current is delivered through the circuit.

Short Circuit Failure

One of the most common problems with a stepper motor is the motor’s failure. This is because the power supply runs excessive current through the device.

In the event of a short circuit, a failure in the wiring can cause a severe issue in the motor stepper.

If your system is prone to short circuits, it is possible to use overload protection equipment to repair the damaged stepper motor.

Winding Damage

The most frequently encountered issue by the stepper motor is the damaged windings.

According to the experts’ suggestions, I replaced this with the oil and filter components. Professional mechanics may encounter issues with Stepper Motor Pawls.

This pawl regulates the pulley’s primary position through its loading valve. If it’s not working, it can cause the transmission to get trapped in the gear.

I typically notice when my shifter shifts, but the gear does not change in this particular instance.

You should bring your stepper motor to the closest auto repair shop for assistance from professional mechanics should it experience any issues.

Why Are CVT Stepper Motors a Problem?

Utilizing the wrong Breadboard

To connect the stepper motor with a standard stepper driver, use a breadboard to combine the two.

Traditional breadboards are designed to permit the core wire to be solid, which is about 0.6mm (or 24 AWG to guarantee a secure and constant connection.

However, most cables from stepper motors don’t have solid cores but are made up of several small cables, resulting in smaller wires than what the Breadboard would expect.

When checking for errors, any movement on incorrect breadboard wires can lead to an instantaneous loss of connection and damage to the stepper motor.

Disconnected Stepper Motor Wires

The cable for the stepper motor gets disconnected when the driver is on. This is the most common reason why your stepper motor fails.

In this situation, it is not recommended to repair the malfunctioning motor or controllers, especially motor connections, even if the power is in use. This is a must for both technicians and drivers.

The problem is that the has been shorted. Winding and Case Problem with Motor Case Problem

The damaged stepper motor’s windings or casing can cause a failure in the stepper motor.

If you can pinpoint the problem, don’t try to fix the problem by opening the stepper motor because this can cause the motor to lose its magnetism and decrease its performance.

Unfavorable Environmental Factors

Unfavorable environmental conditions can create a negative step motor.

These elements could be dust and chemical vapors, weld and moisture, humidity, and metal debris that could damage the stepper motor in your vehicle and electronic components.

Back-driven Stepper Motor

It is essential to understand that a load could turn the stepper motor, generating a back EMF voltage within the driver. The higher the speed is, the greater the voltage.

This voltage could cause damage to the driver if it is excessively high than usual.

The motor running in reverse when the power is on is extremely risky to the motorist. Use a mechanical brake or stop at any time when these types of events occur.

What happens if a CVT Stepper Motor Breaks?

Be careful to avoid driving with a failed stepper motor. A damaged stepper motor can make the engine less efficient and perform.

Additionally, motor inefficiency may draw a lot of energy. Additionally, the poor stepper motor could cause torque to drop rapidly.

Another issue with the defect in the stepper motor is the need for more steps, which makes the engine run inefficiently.

Image Source: Richard McCuistian.

How do you repair a defective stepper motor for a CVT?

If you’re seeking a simple solution for resolving problems with the stepper motor, I suggest looking into some alternatives.

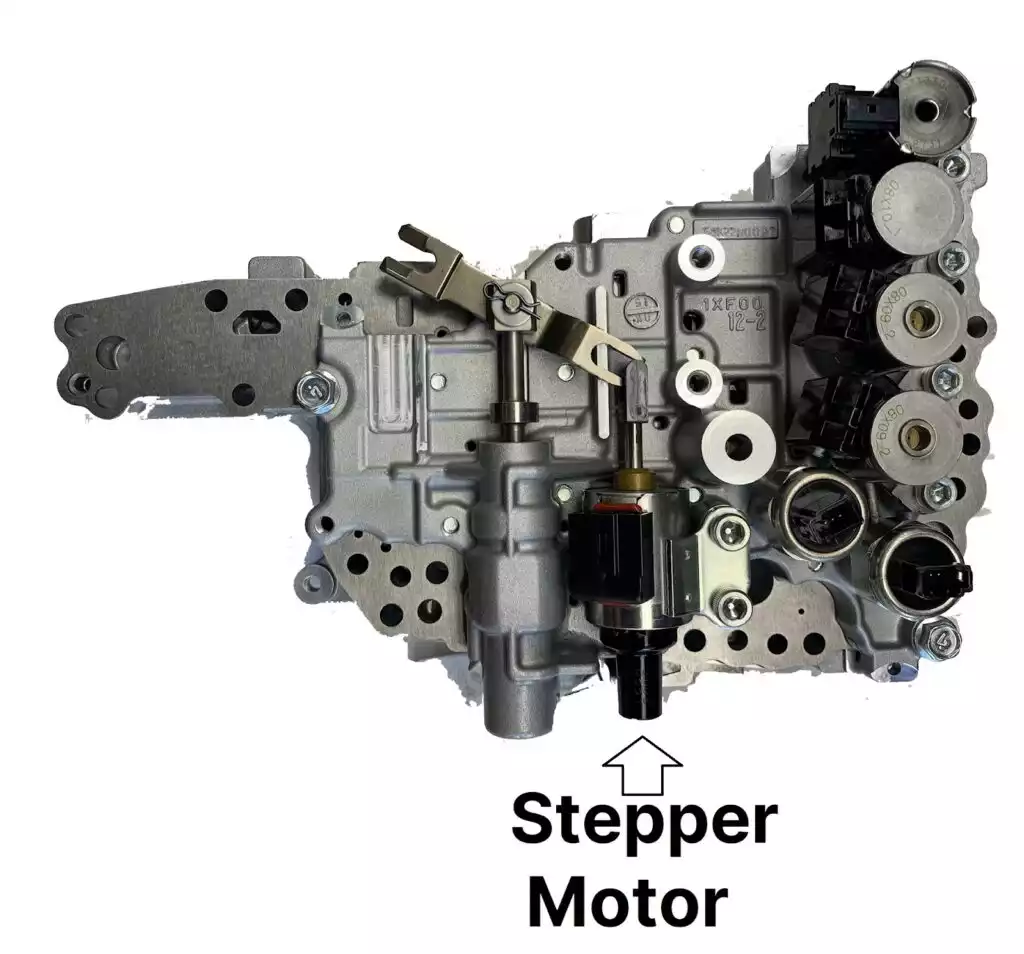

First step: Take out the defective stepper motor and replace it if you have secure and reliable tools. It is possible to do this by removing the old transmission oil from your vehicle.

Then, pull the pan to remove the oil from the transmission and scrub it clean using brake cleaner.

Step 2. Continue taking off both the valve’s body and the transmission filter. Then, remove the three bolts that secure this filter onto the car. If the bolts are loose, remove the filter.

Step 3. Now, you must remove the fasteners that connect the body of your valve to the car and a set of bolts to take off from the body of your valve.

Step 4:Drag on the motor of the stepper and then replace the engine with a new one. After that, you can reinstall the entire system in the same way.

FAQs

What Does the Code P1778 What Does Code P1778

The code can be interpreted as a code for Nissan. It occurs if an ECM or PCM detects an indication of a problem due to or malfunction of the Step motor of the transmission function.

What is the cost of the replacement of Nissan Stepper Motors?

It is estimated that the Nissan Altima step motor replacement price can vary between $2,000 and $4,000. Sometimes, you can repair and replace the defective stepper motor to cut costs.

Conclusion

Being anxious and angry is normal if your Nissan seems to have problems with the CVT stepper motor issues.

This leaves your vehicle equipped with CVT transmissions more prone to various issues.

Therefore, when you identify an inefficient stepper motor as the primary source of CVT transmission problems, Replace it to repair the issue and boost the performance of your Nissan.

A damaged stepper motor may result in a jerky or hesitation sensation as your vehicle speeds up or is across the road.

Additionally, it could cause strange sounds to alert you to the peculiar issues within the system.

The inspection of your stepper motor is vital to ensure you get the proper repair or replacement to allow your vehicle. It will enable it to function better.